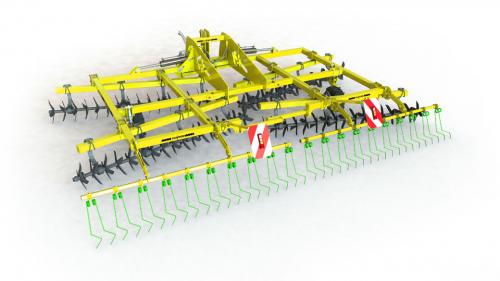

Claydon Terrablade

The Claydon TerraBlade inter-row hoe is a low-cost, mechanical method of controlling weeds in combinable, band-sown crops.

Description

The Claydon TerraBlade inter-row hoe is a low-cost, mechanical method of controlling weeds in combinable, band-sown crops. It provides an additional weapon in the agricultural industry’s weed control armoury at a time when the efficacy of some herbicides is decreasing whilst the cost of control is increasing.

Band sowing at 30cm leaves a 14-15cm-wide unseeded strip between the rows which can be mechanically hoed.

The TerraBlade eliminates weeds from that area reliably, safely and without using chemicals. This clears up any weeds that were missed by ag-chems, or where such products cannot be used, greatly reducing the return of weed seeds and the overall weed burden.

By keeping the unseeded rows clear of weeds during the early stages of crop growth, competition for nutrients, light, air and water is reduced and the young plants can grow away strong and healthy.

TerraBlade has the potential to improve crop yields, drastically lower the potential for carry-over of weed seeds and reduce the risk of more resistant types developing.

The unit will give years of reliable service, has very low operating costs and offers great flexibility. It is designed with a Cat II front linkage and travels at speeds of approximately 6 km/h and up to 30mm deep.

It is manually steered and can be used whenever soil conditions allow, covering up to 40ha a day with a 6m unit. On farms that drill early, crops may be suffi ciently well developed in the autumn to start TerraBladeing then, and in the spring the operation can continue whenever soil conditions allow, up to the stage where the crop might be compromised by further passes.

The TerraBlade has been designed for use in all types of strip seeded crops.

Additional information

| condition | |

|---|---|

| make |

Video

Claydon Direct Seed Drills

Claydon Drills are the most renowned direct strip till seeding system in Europe, giving sustainable high yield results year on year with huge environmental benefits. Their seed drills can be used direct into stubble or cultivated soils giving huge time and cost savings when used as a direct drill.

The leading tine can be adjusted to a depth of between 0 for low disturbance and 15cm (6 inches) for deep rooting crops like OSR. The second tine can be adjusted via the depth wheels to put the seed in as shallow or deep as necessary.

- Centrally mounted depth wheels give very accurate seed placement as they run on undisturbed soil between the rows and do not run over or cap the seeded area.

- Stone protected leading tines break through the ground lifting and aerating it whilst creating a drainage tract and space for the roots to grow deep and strong with ease.

- Solid sprung seeding tines keep a highly accurate and constant seed depth, flowing through the soil lifted by the leading tines and cultivating it whilst only moving for a large stone.

- Levelling boards and tines leave a superbly level finish covering the seedlings in a perfect soil plant pot with drainage and space for root development.

- Fertiliser can be placed below the seed (front tine) or above the seed (rear tine) with the standard tine set up. With the twin tine option, fertiliser can be placed below the seed only.